4th Annual Research Spotlight Meeting 2023

The Plant Protein Innovation Center (PPIC) hosted its Fourth Annual Research Spotlight Meeting on March 29-30, 2023, at the University of Minnesota. This year, PPIC welcomed 150 individuals from over 65 companies and organizations involved in plant protein research and development. Keynote speaker, Dr. Nesli Sözer, Research Professor, VTT Technical Research Centre of Finland presented on “Processing Technologies to Design Plant-Based Dairy and Meat Analogues”. According to Dr. Sözer, “The fruitful discussions between industry and academia representatives attending the PPIC research spotlight meeting have not only nourished new collaboration ideas but also cultivated a shared commitment towards sustainable food systems. The success of this event reinforces the notion that when diverse perspectives (from breeding to processing to consumer) come together, the possibilities for progress are endless.”

In addition to her presentation, renowned researchers from 9 national and international institutions and organizations presented research summaries on protein structure, functionality, flavor interactions, nutrition, and breeding of various sources of plant proteins.

This year’s event featured two panels of industry representatives who led discussions on plant-based food products and plant protein ingredients. The panel discussions were preceded by an overview by Dr. Shelley Balanko from The Hartman Group who presented on the consumer trends in the plant protein category.

Attendees also engaged in interactive poster sessions. Posters featuring current PPIC funded as well as other research projects were presented. The sessions allowed guests to meet students and post-doctoral researchers and learn about their progress. “These poster sessions are a great benefit to both the student researchers and industry,” notes PPIC Director Prof. B. Pam Ismail. “Students get the opportunity to showcase their work, while industry participants get to ask questions about the research and connect with future research talent for hire.”

During the networking sessions, several PPIC member companies hosted booths to share their ingredients/products, technologies, and engineering capabilities with the attendees. These sessions paved the way for future collaborations.

4th Annual Research Spotlight Meeting

Speakers

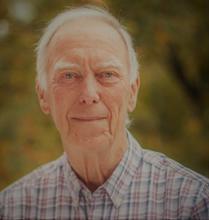

Nesli Sözer, Research Professor, VTT Technical Research Center of Finland

Keynote Speaker

Biography

Nesli Sözer is a research professor at VTT Technical Research Centre of Finland. VTT is one of Europe’s leading research institutions. Owned by the Finnish state, VTT is involved in the advancement, utilisation and commercialisation of research and technology in commerce and society. Nesli has more than 20 years expertise on food material science and food ingredient/product design. Nesli is passionate in immersing food science and technology into novel concepts. Currently, she is leading international (funded by Horizon Europe) and national (funded by Business Finland and Academy of Finland) projects focusing on plant proteins, meat and dairy alternatives and decentralized personalized food production. She has a Ph.D. degree in Food Technology and held post-doctoral positions at the University of Illinois and Rutgers University prior to joining VTT almost 12 year ago.

Presentation: Processing technologies to design plant-based dairy and meat analogues

Climate change, natural resource scarcity and fast-growing world population is threatening our access to nutritious, safe and affordable food. The protein supply is in this respect the most critical. Meat or dairy analogues are products manufactured mainly from plant-derived ingredients to mimic the taste, texture, and cooking features of animal counterparts. Majority of the current meat and dairy alternatives are mainly based on soy or wheat but opportunities are beyond these two crops. Dr Sözer’s talk will first introduce sustainable protein separation technologies based on air classification and cascaded use of air classification with wet extraction. She will also present a recently patented novel protein separation technology based on extrusion processing. Next, she will give case examples how bioprocessing technologies (enzyme and microbial) as well as precision fermentation can be utilized to overcome challenges in plant based dairy and meat analogues.

James House, Professor, University of Manitoba

Biography

Dr. House is a Professor in the Department of Food and Human Nutritional Sciences, University of Manitoba. He completed his Ph.D. in amino acid nutrition and metabolism from the University of Guelph, Ontario, Canada in 1996. Since arriving at the University of Manitoba in 1998, he has maintained research programs in 3 primary areas: 1) understanding factors regulating sulphur amino acid metabolism in animals; 2) sustainable egg production systems, including novel value-added egg products; and 3) determining factors influencing the quality of dietary proteins. To date, he has published 146 peer-reviewed manuscripts, and has an h-factor of 36 (Scopus). His research program has trained 40 graduate students and 15 post-doctoral fellows, as well as over 40 undergraduate research assistants. His research program has advanced our understanding of factors affecting the utilization of plant- and animal-based protein sources in the human diet. He has received awards from the Canadian Society of Animal Science, the Canadian Society of Nutritional Sciences (now the Canadian Nutrition Society), as well as awards for merit and administrative service from the University of Manitoba. Dr. House has served as President for the Canadian Nutrition Society (2018) and was recently elected (2021) as a member of the Board of Trustees for the newly established Institute for the Advancement of Food and Nutrition Sciences (IAFNS). His research program is funded via NSERC Discovery Grants, as well as numerous tripartite funding programs involving industry and government partners. He is the program lead for the Manitoba Protein Research Strategy.

Presentation: The Effect of Processing on the Nutritional and Technofunctional Properties of Chickpeas.

Chickpeas represent an important pulse crop globally. Production of chickpea in North America is principally located in the Northern plains of the US and the Western Prairies of Canada. However, domestic consumption of whole chickpeas is limited, and further processing represents an opportunity to add value locally through the creation of novel plant-based protein ingredients. Examples of current processing methods include milling, air classification (to create protein concentrates) and aqueous extraction methods (to create protein isolates). Alternative approaches to process chickpeas into food ingredients include thermal processing methods such as extrusion and micronization, as well as biological methods, including germination. The primary goals in the use of various processing steps include the maintenance or enhancement of the nutritional and/or technofunctional (e.g. emulsification properties; water/oil holding capacity; foaming capacity) quality parameters of the chickpea products. In relation to nutrition, protein quality is key for plant-based ingredients, as it is important for the substantiation of protein content claims for foods as well as defining the overall protein value of the food or ingredient in question. Recent research has explored how protein quality (digestibility; amino acid composition) can be modified by milling, fractionation processes and thermal processing. Furthermore, these same processes can alter the levels of certain plant constituents deemed to be anti-nutritive (e.g. phytate; trypsin inhibitors). A thorough understanding of the impact of processing on the nutritional and technofunctional properties of chickpeas will enhance the utilization of this pulse in novel food applications.

Osvaldo Campanella, Professor, Ohio State University

Biography

Professor Osvaldo Campanella is the Carl E. Haas Endowed Chair in Food Industries at the Department of Food Science and Technology at the Ohio State University since 2019. Previously he was at Purdue University in the Agricultural and Biological Engineering Department, a member of the Whistler Carbohydrate Research Center and the Department of Food Science. Prior to Purdue, he was also a faculty member at Massey University in New Zealand. Professor Campanella has published more than 250 scientific articles related to extrusion rheology, and food process engineering. He has published two books related to the extrusion processes for food and non-food biological materials and the science and technology of fibers in food systems. Professor Campanella holds a degree in Chemical Engineering from the University of Buenos Aires, Argentina and a PhD in Food Engineering from the University of Massachusetts, USA.

Presentation: Applications of texturization of biopolymers to produce nutritious and high-quality food products

Texturization of proteins has become a useful processing tool for creating foods with improved textures and nutritional qualities. Therefore, a systematic and in-depth understanding of the effects of formulation and texturizing mechanisms on the final quality of the product is necessary. Key parameters that are associated with texturization and different types of manufacturing processes to texturize as well as their effects on product quality will be described.

Buddhi Lamsal, Professor, Iowa State University

Biography

Dr. Lamsal is a Professor of Food Processing and Engineering at Department of Food Science and Human Nutrition at Iowa State University and a certified Agricultural Engineer in the state of Iowa. He has been engaged in plant protein research for 18 years, primarily studying proteins’ structure-functional relationship, functionalizing plant proteins for food applications, and characterizing their ingredient function. He also worked in fermentation-based modification of protein, especially for monogastric feed digestibility. Currently, Dr. Lamsal’s research involves high-power sonication based improved extraction procedure for plant proteins (soy and legume proteins) and its effect on protein quality and broader range of ingredient functionality. Professor Lamsal teaches Food Processing to undergraduate and graduate students. He has published more than 80 peer-reviewed journal articles, 6 book chapters, and 2 edited books. Dr. Lamsal is an active member of scientific professional societies, AOCS and IFT.

PRESENTATION: Impact Of High Power Sonication On Protein Extraction From Defatted Soymeal, And Comparative Gelling Properties Of Mung Bean Protein Treated With Sonication And Atmospheric Cold Plasma

Some of the challenges for plant/seed proteins are that they have relatively low extraction yields and inferior functional/ nutritional aspects. Various food processing techniques (physical, enzymes) can be used to enhance extraction performance and modify ingredients’ functional characteristics for example, dispersion rheology, gelation, and surface activities like emulsion and foaming. This presentation will cover the effect of high-power sonication (HPS) on extraction yield and isolate preparation from soymeal, as well as the impact of cold-plasma treatment of mungbean protein on gelation.

B. Pam Ismail, PPIC Founder & Director, Professor, University of Minnesota

Biography

Dr. Pam Ismail is the Founder and Director of the Plant Protein Innovation Center and is a Professor at the Department of Food Science and Nutrition, University of Minnesota. Dr. Ismail has over 25 years of experience in Food Chemistry research focused on analytical chemistry, protein chemistry, and chemistry and fate of bioactive food constituents. Her research focuses on structural characterization and enhancement of functionality, safety, bioavailability, and bioactivity of food proteins, following novel processing and analytical approaches. She is the recipient of a “Distinguished Teaching Award” and an “Outstanding Professor Award”.

Presentation: Pea 7S Vicilin to 11S Legumin Ratio: Convoluted Impact on Functionality

Variability in pea protein functionality goes beyond differences in extraction and processing conditions. Processors are baffled with the extent of variation between different pea protein lots, let alone different pea protein ingredient sources. It is commonly assumed that soy protein is superior to pea protein in various functionality due to differences in 11S legumin to 7S vicilin ratio and composition. But the story is not complete. This presentation will shed some light on how the 11S to 7S ratio may impact pea protein functionality in comparison to soy protein, and whether the ratio alone can be the culprit behind the extent of frustrating variability in pea protein functionality.

Brennan Smith, Research Leader, US Department of Agriculture

Biography

Brennan Smith PhD. is the Research Leader for the Food Processing and Sensory Quality Research Unit at the USDA-ARS Southern Regional Research Center in New Orleans, LA. He oversees a diverse set of research projects involving rice quality and utilization, tree nut and peanut allergy, warm water aquaculture, catfish quality and utilization, and alternative protein research. His primary research interest is food security as it relates to the future availability of dietary protein. His current research focuses on protein characterization of agricultural commodities, as well as protein isolation, modification, and application into foods.

Presentation: Assessment of Pea Protein Variability

Through the assessment of 47 pea varieties, it was found that the protein profiles of peas are highly variable between cultivars. To better resolve this variability, the protein profile of individual seeds from two cultivars of peas grown at the same location and year were assessed. The vicilin/legumin ratio (V/L) was found to range from 2.72–4.19 for one variety and 1.70–2.22 for the other. Higher V/L is thought to provide better gelling and texturization characteristics. This lack of protein conservation needs to be considered for process optimization and scale-up from laboratory to commercial settings.

Jim Anderson, Professor, University of Minnesota

Biography

Jim Anderson is a Professor in the Department of Agronomy and Plant Genetics at the University of Minnesota where he leads the spring wheat breeding program and provides guidance to new breeding programs on intermediate wheatgrass (Kernza®), field pennycress, and camelina. Research on each species includes the investigation of breeding/genetic principles related to crop improvement, focusing on locating genes underlying economically important traits and implementing marker-assisted and genomic prediction for cultivar and germplasm development.

Presentation: Breeding Camelina as a Winter Oilseed Cover Crop for Minnesota

We are breeding winter type camelina as an oilseed cover crop to protect soil and water resources, providing oil that can be used as a fuel or food and meal that is suitable for animal rations and human food applications. Breeding activities have focused on breeding for earliness to improve camelina’s suitability for use as a relay crop with soybean and increasing seed and oil yield. More than 90% of the world’s camelina germplasm is spring type and we are utilizing this germplasm to diversify our small base of 14 winter accessions.

Shelley Balanko, Senior Vice President, The Hartman Group

Consumer Trends

Biography

Shelley Balanko has an informed understanding of social and cultural influences impacting the marketplace. Shelley regularly engages diverse audiences spanning foodservice, consumer packaged goods and retail as she shares leading-edge consumer insights and implications. Shelley graduated from the University of Windsor with a Ph.D. in Applied Social Psychology. She has a MA in Applied Social Psychology from the University of Saskatchewan and a BA in Psychology from the University of British Columbia.

Presentation: Consumer Trends in the Plant Protein Category

The Hartman Group is the premier food and beverage consultancy. Since 1989, The Hartman Group’s anthropologists, social scientists and business analysts have been immersed in the study of food and beverage culture, using ethnographic observation, quantitative tracking surveys and deep study of trends. What we have learned and continue to uncover allows us to upend many notions of our traditional eating and drinking patterns, thereby identifying unique opportunities and winning strategies for our clients. For more: www.hartman-group.com.

Mirko Bunzel, Professor, Karlsruhe Institute of Technology (KIT), Germany

Biography

Dr. Bunzel is a Professor at the Department of Food Chemistry and Phytochemistry at the Karlsruhe Institute of Technology (KIT), Germany. Prior to joining KIT, he was an Associate Professor at the Food Science and Nutrition Department of the University of Minnesota (2007-2011). His research focuses on plant cell wall polymers such as polysaccharides and phenolic polymers. His group develops chromatographic and spectroscopic approaches to structurally characterize these highly versatile polymers. These methods are applied in order to monitor changes of plant cell wall polysaccharides during ripening, storage of plant based foods, and food processing, but also to understand physiological processes such as fiber fermentation in the human colon and in ruminants.

Presentation: Carbohydrate analytical tools to monitor upcycling processes of plant based by-products

Plant based by-products from primary agri-food production are widely available and often used as low-value materials, such as feedstocks for biogas, forages etc. These by-products are generated, among others, in the production of protein isolates (from lupins), starch (from peas), sugar (from sugar beet), oil (from canola), and juice (from apples, carrots). Although they differ in their overall composition, these residues have in common that they are rich in non-starch polysaccharides. These non-starch polysaccharides can be used as thickeners, gelling agents, dietary fibers with different technofunctionality and/or physiological effects, emulsifiers, etc. The field of application depends on the composition and the structural features of the polysaccharides in the by-product, their extraction and/or possible modifications (enzymatic, mechanical, hydrothermal etc.). To determine the polysaccharide composition and chemical structures in the by-products and to monitor changes during the extraction and modification processes, analytical tools capable of detecting structural changes of these largely variable polymers are required. In this presentation, HPAEC-, MS-, and NMR-based analytical tools and their application to by-products and in the upcycling process of these by-products will be presented.

Gary Reineccius, Professor Emeritus and Past Head, University of Minnesota

Biography

Dr. Gary Reineccius has been actively involved in flavor research for more than 50 years. During this time he has published over 250 research articles. His research focuses on two areas: flavor related challenges and ingredient encapsulation. Flavor work has been quite broad covering methods for flavor analysis, off flavor identification and remediation, flavor release in the mouth when eating and its encapsulation (protection and controlled release). Currently his group is conducting three research projects focused on plant proteins. One project is focused on reducing the inherent flavor of protein isolates (reduce objectionable flavors). A second project is focused on the improving the stability of flavorings when added to foods containing plant protein isolates. We have provided data to show that added flavorings may contain components that are readily lost to covalent bonding with proteins. These losses will reduce product shelf-life. A third project is focused on finding ways to reduce flavor: protein reactions. At this time, the effort is to evaluate the potential of moderate glycation to block reactive sites in proteins.

Presentation: Flavor reactions with plant proteins

This project is focused on determining how the reactions between flavor compounds and plant proteins influence the ability to successfully flavor (initially and during shelf-life) foods made using them. We were able to use a mass spectrometric method to study flavor reactions with small proteins (e.g. β-lactoglobulin) but plant proteins are much larger in molecular weight and thus, cannot be used to study flavor reactions with them. After much development effort, we now have a C14 labeled flavor compound method to study these reactions with plant proteins. Our approach is to make up an aqueous solution of the protein isolate of interest, add a known quantity of C14 labelled flavor compound, allow reaction time, solvent extract all free, non-covalently bound flavor compound and then do a C14 count of the reacted protein solution. At this time we have: 1) shelf-life data (loss over time at 25, 35 and 45 C storage for 4 weeks – analyzed weekly) for decanal, 2-phenylethyl isothiocyanate and decane, 2) data for the loss of decanal, vanillin, decane and 2-phenylethyl isothiocyanate when heated at 90C for 1 hr (high temperature treatment); and 3) Most recently we have completed an comparative evaluation of WPI, Pea Protein, Hydrolyzed Pea Protein, Soy, Pennycress and Camelina for reactivity with the same flavor compounds during thermal processing. Isothiocyanate was found to be most reactive flavor compound tested followed by decanal, vanillin and the control, decane (no reaction). A commercial hydrolyzed pea protein isolate was much more reactive that the precursor pea protein isolate.

Yonghui Li, Associate Professor, Kansas State University

Biography

Dr. Yonghui Li is an Associate Professor and Director of the Wheat Quality Lab at Kansas State University. His research focuses on understanding the structure, chemistry, interaction, and functionality of proteins and other components for the development of quality and functional grain foods and ingredients. He has received over $4.2M funding from the USDA, KS grain commissions, and grain and food industries. He has published 100+ journal articles and two patents. He is an associate editor for the Journal of Food Science and editorial board member of multiple journals.

PRESENTATION: Developing functionally enhanced pea proteins as innovative food ingredients

Proteins are essential food components providing both nutritional and functional benefits. In recent years, there has been a growing trend towards using plant proteins in various foods. However, native plant proteins, such as pea protein, can have limitations in their functional properties and may not be suitable for all food applications. During this presentation, Dr. Li will share their research on how they have improved the functional properties of pea protein through biochemical and enzymatic processes, as well as the underlying structure-functionality relationships. He will also highlight the practical applications of modified pea proteins in products such as emulsified dressings, meat extenders, and texturized proteins.

Belal J. Muhialdin, Research Specialist, University of Minnesota

Biography

Dr. Belal Hasan is a Research Manager at Ubbink research group at The Department of Food Science and Nutrition, UMN, with a background in Food Biotechnology. He has 11 years of experience that was gained after working at the Department of Food Science, Faculty of Food Science & Technology, Universiti Putra Malaysia as a Postdoctoral Fellow and Senior Lecturer. Dr. Belal received his BSc in Food Science and Technology (2007), MSc in Biotechnology (2011) and PhD in Food Biotechnology (2014). His research is focused on technological functionality and biological activities of food proteins.

Presentation: Development of a new method to measure the degree of texturization of extruded meat analogues

Plant protein concentrates and isolates are converted into fibrous matrices resembling meat using high moisture extrusion. A major challenge in the optimization of ingredient formulations and extrusion conditions is that there are few experimental methods measures to quantify the degree of texturization with sufficient precision. Current approaches to quantify the degree of texturization are mostly based on either imaging methods or texture analysis. While intuitive, it turns out that the method is imprecise with a large experimental variability. We propose a new method to determine the degree of texturization of meat analogues based on their swelling behavior in water. We introduce the swelling anisotropy index (AIswelling) as the ratio of the aqueous swelling strains in the longitudinal and transversal directions. Our swelling index shows that extruded pea protein isolate (PPI) matrices are anisotropic, with the longitudinal swelling strain being significantly larger than the transversal swelling strain for most samples. The anisotropic swelling is interpreted in terms of the molecular conformation of the protein chains that can be influenced by processing conditions such as screw speed, temperature and water content. We demonstrate the usefulness of the novel index that may be of significant practical importance in characterizing plant protein matrices that mimic the anisotropic properties of meat.

Stay up-to-date on the latest in plant proteins research from expert researchers that are part of the first plant-based research center of its kind in the nation.